Innovative and efficient

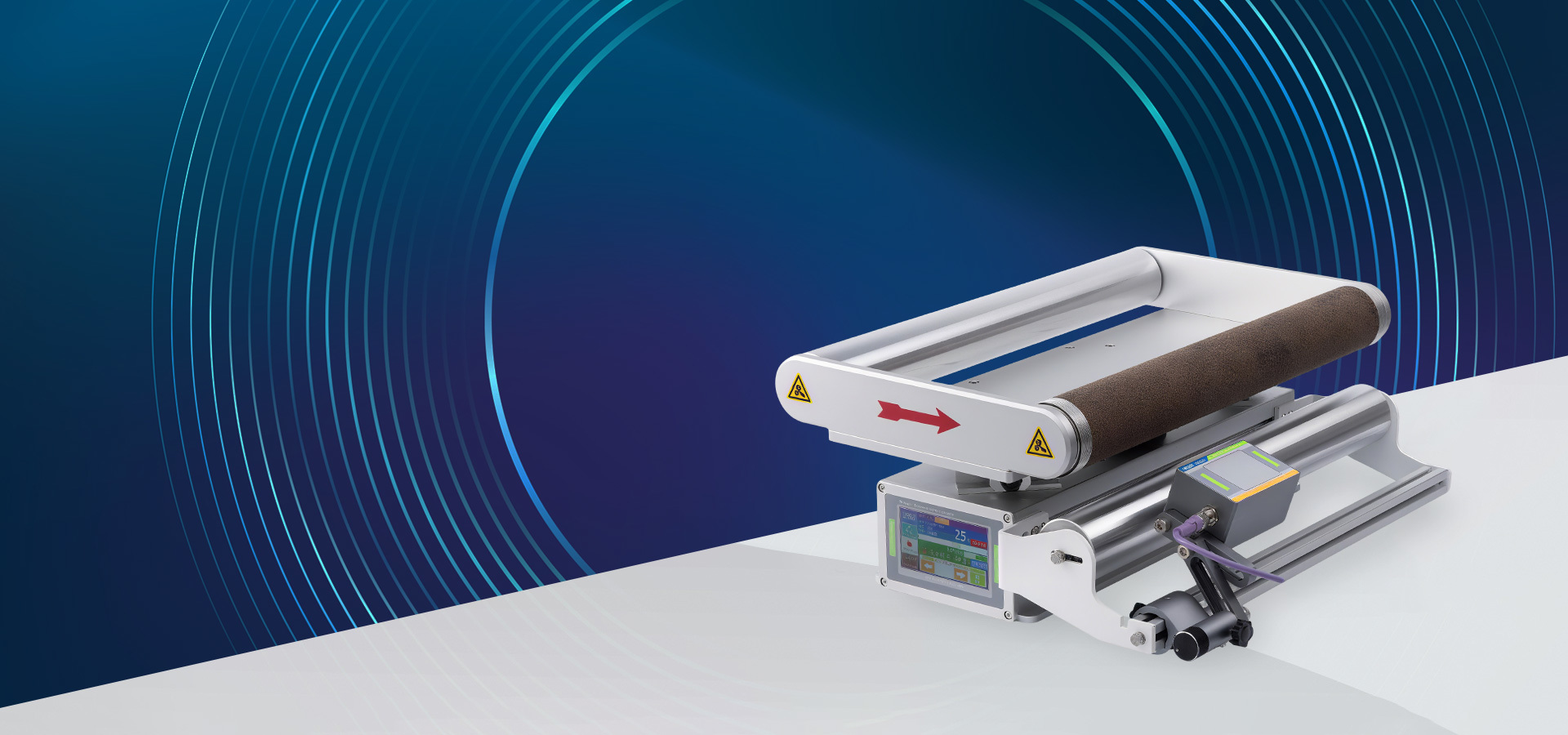

KCON Solutions for Web Guiding Systems

Higher performance” is the standard of our products: KCON systems ensures consistent, first-class production results in web processing industries and make a significant contribution to making production processes faster and achieving sustainable increases in productivity.We aim to ensure that all our customers gain the greatest economic benefits from our professional consulting services and outstanding technical support.

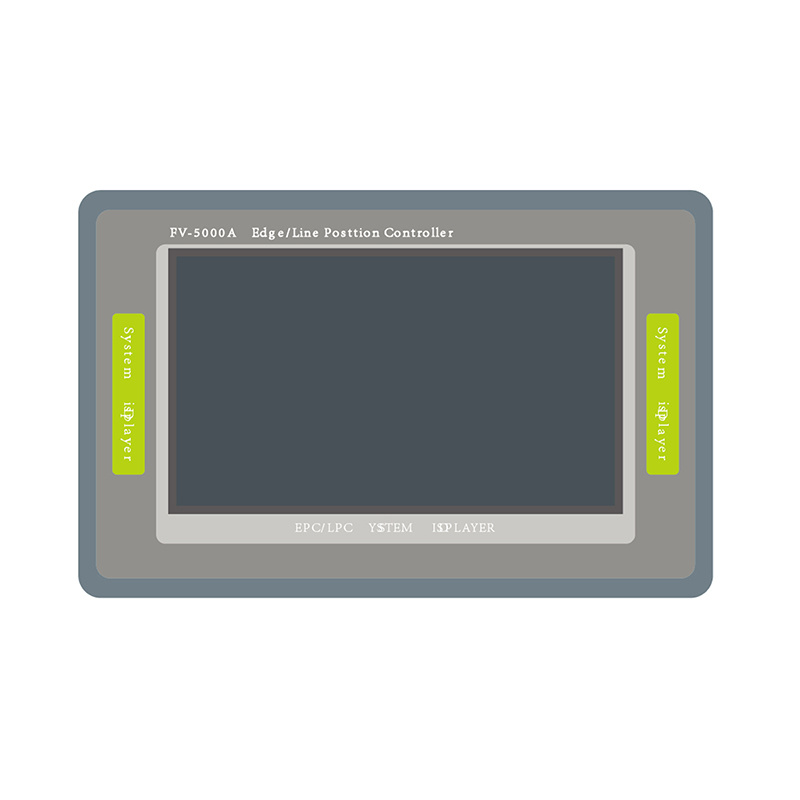

FV-5000A controller

FV-2000 controller

FV-360 controller

PC type magnetic powder clutch

PC type magnetic powder clutch with base

PC-A2 type hollow magnetic powder clutch

Standard-definition Inspection System

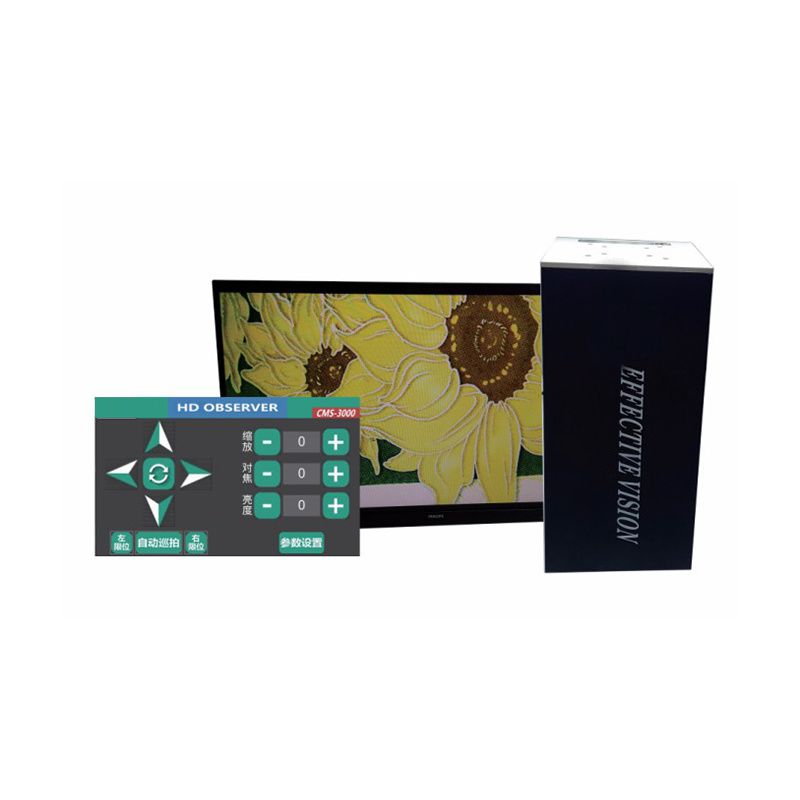

High-definition Inspection System

Grouped Register System

Centralized Register System

S Series - Corona Machine Controller

F Series - Corona Machine Controller

Y Series - Corona Machine Controller

Oil-immersed high-voltage discharge station

Web guiding systems for improved quality and productivity

Today, manufacturers and users of processing machines are faced with ever-increasing quality requirements, not only in terms of production and processing speeds, but also in terms of precision and product quality, but also in terms of minimizing the number of personnel, wear and tear, and downtimes. However, these prerequisites are first of all a perfect material guiding system. Typically, the material enters the processing section from the unloading axis and is then wound up and rewound, and in each stage of the process, there will be a displacement generated. LPC (Line-edge Position Control) to the line to the edge of the tracking device is the use of accurate photoelectric detection, to control the volume of material at any time can be corrected to maintain a neat and correct position, also known as deskewing device. It is widely used in all kinds of industrial machinery to improve quality, reduce loss and reduce labor, and is the backbone of industrial automation.

Application Areas

The products are mainly oriented to printing, packaging, rubber, labeling, textile, electronics, iron and steel, chemical, pharmaceutical, lithium battery, corrugated paper, sanitary products and other industries, and are widely used in printing presses, slitting machines, bag making machines, coating machines, film blowing machines, paper making machines, rewinding machines.

Innovator in the field of intelligent guiding

Wuxi Kcon Optoelectronics Technology Co.,Ltd.

As an innovator in the field of deflection correction, our goal is to provide you with innovative and efficient solutions for deflection correction systems that meet your every need.

High precision is not only an important measure, it is also a characteristic of all our products and services. With more than 15 years of experience in the deflection correction industry, our expertise when it comes to the selection and application of deflection correction systems is unquestionable. We are happy to share our expertise with you on how to select and apply a deflection correction system.

Our ultimate goal is to enable all users to maximize the economic benefits of our professional consulting services and excellent technical support.

Staffing

Professional technicians to solve difficult problems; professional KCON service network management/action system; these ensure that users get the most convenient, timely and effective help.

Technical Support

KCON carries out systematic, multi-level, frequent cycle training for technicians, and constantly improves the overall quality of technicians to give users strong technical support.

Spare Parts Supply

KCON has established a perfect maintenance operation standards, and the use of customer surveys, tracking calls back to the comprehensive performance evaluation and other methods of maintenance personnel to carry out strict supervision of service quality, to ensure that the service is of high quality.

Why Choose Us?

01

Reliable Quality

—

We set quality assurance and production optimization standards, and we always think and act globally. This means that you will always receive the best service and solutions available anywhere in the world.

02

No maintenance required

—

Modular design, high stability, no vulnerable components, energy-saving and environmentally friendly, no maintenance required.

03

Easy operation

—

Any automatic control is based on simple control loop. Even

complex tasks can be decomposed and simplified into these

Control loops.

04

User friendly

—

4.3-inch large screen full-color display, pure touch operation. With a parameter classification setting guide, digitization is clear at a glance.

05

Space-efficiency

—

The design of products are suitable for space limited applications, while maintaining stable accuracy.

06

Strong anti-interference features

—

Our products boast strong anti-interference features suitable for demanding work environments, alongside high reliability and an extended service life.

07

Low voltage 24 V

—

KCON products technology has been specially developed for use in low-voltage 24 V DC voltage applications.

08

Incremental encoder

—

Our drives are equipped with a incremental encoder for precise speed and position feedback without the need for a data storage medium.

09

Ambient temperature up to 50°C

—

KCON Products are optimized for use all around the world and retain their full performance capabilities up to ambient temperatures as high as 50°C.

Blog

Standard-Definition Inspection System Continues to Play a Vital Role in Industrial Quality Control

As manufacturing and industrial production continue to evolve toward higher efficiency and tighter quality requirements, inspection technologies remain a core component of modern production lines

14 Jan,2026

The Role of Magnetic Powder Brakes in Modern Industrial Applications

The magnetic powder brake provides smooth, adjustable torque control, ensuring precise and reliable braking for industrial machinery and testing equipment.

07 Jan,2026

Creating value for you with professionalism and technology, respecting all partners

As an innovator in the skew correction field, we provide innovative and efficient skew correction system solutions, with high precision as the core characteristic. Relying on 15 years of industry experience, we have professional advantages in selection and application, and are happy to share our knowledge. The aim is to enable users to obtain maximum economic benefits through professional consulting and technical support.

Consult Now