Categories

Contact Us

Customer Service Hotline:

Contact Number:

Email:

Address:

No. 9 Plant, 101 Xinjin Road, Xiwu District, Wuxi, Jiangsu Province, China

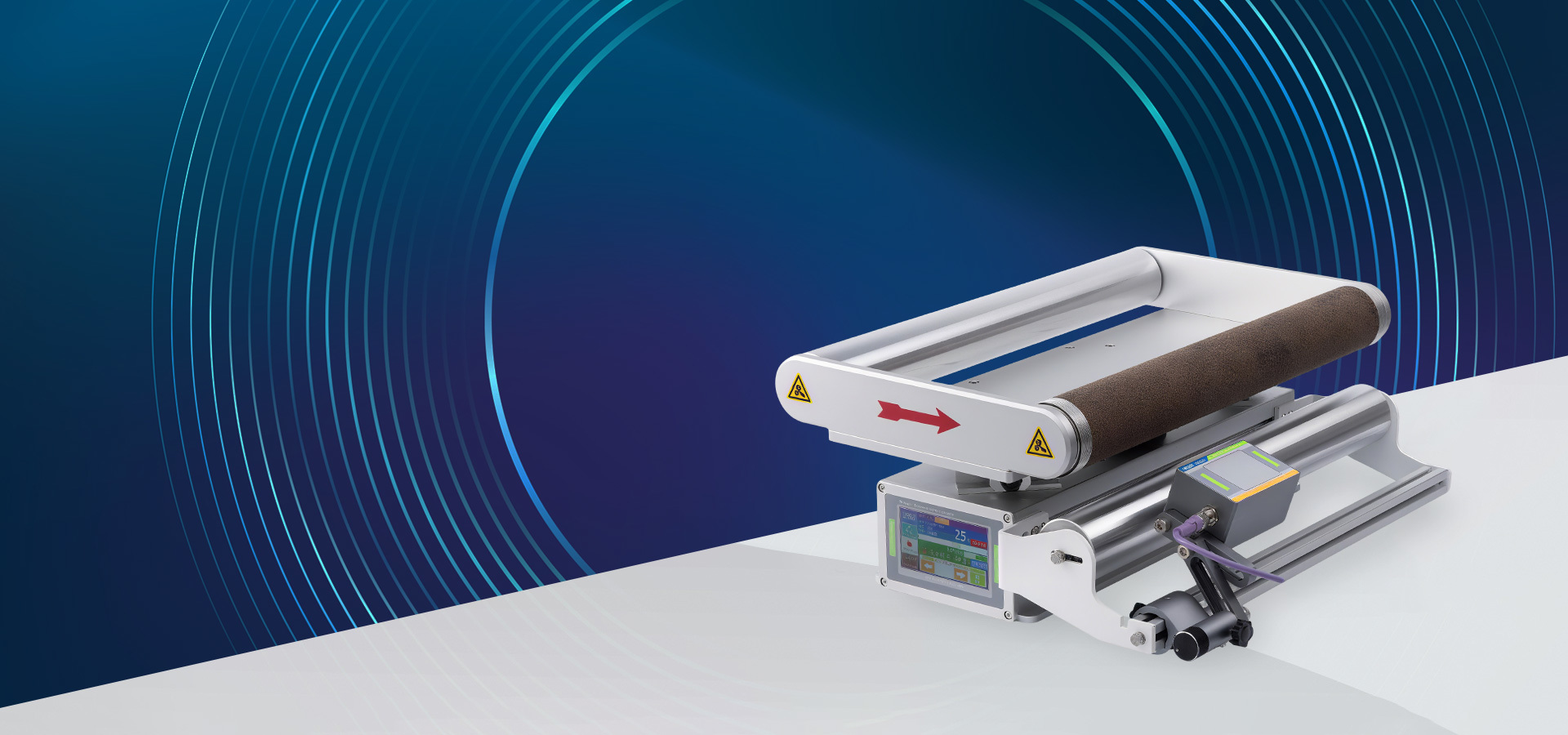

Y Series - Corona Machine Controller

Category:

Consult Now

Consult Now

Product Details

Corona Treater Features Summary

I. The product adopts a split structure. The control system and the high-voltage oil tank are separated, so the high-voltage oil tank can be installed near the discharge rack, which can greatly shorten the transmission distance of the high-voltage line and greatly avoid the impact of the excessively long high-voltage line on the safety of personnel and machines.

II. Integrated drive control design. It can be installed in the cabinet, which is more convenient and beautiful.

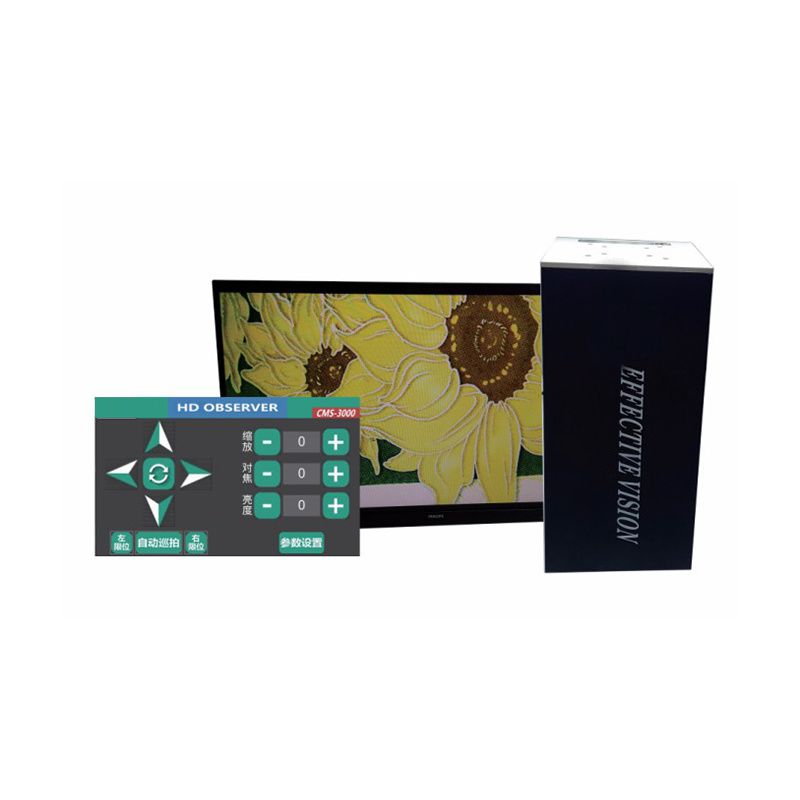

III. The human-machine interface provides digital tube display and touch screen display, which can be used alone or in combination.

IV. The bit control and registers of RS485 can be opened to customers, and customers can design their own host computers (touch screen or PLC) according to their needs, making it easier for customers to use.

V. Rich external ports provide convenient solutions for more functions.

1. For speed sensors, low-cost Hall sensors and high-precision encoder interfaces are available.

2. There are independent external start and emergency stop ports.

3. Small signal OC alarm output and relay alarm output.

4. With material shortage and blockage detection.

5. With automatic power adjustment. Automatically adjust the power output according to the material output speed, without manual adjustment.

6. High-power corona treater with ground current detection. Even if the corona treater works in a very humid environment, the corona treater can still work normally and adaptively, and will not damage the corona control system.

7. Sensitive high-voltage open circuit, short circuit, and overcurrent detection make the equipment run more safely.

8. Automatic adjustment of output power PID makes the output more stable and reduces the impact of power grid voltage fluctuations. Greatly improves product consistency.

Model | Input Voltage | Output Power | Working Frequency | Size |

HBY-Y200 | AC 220V | 2KW | 17-30KHZ | 460X300X220 |

HBY-Y300 | AC 220V | 3KW | 17-30KHZ | 460X300X220 |

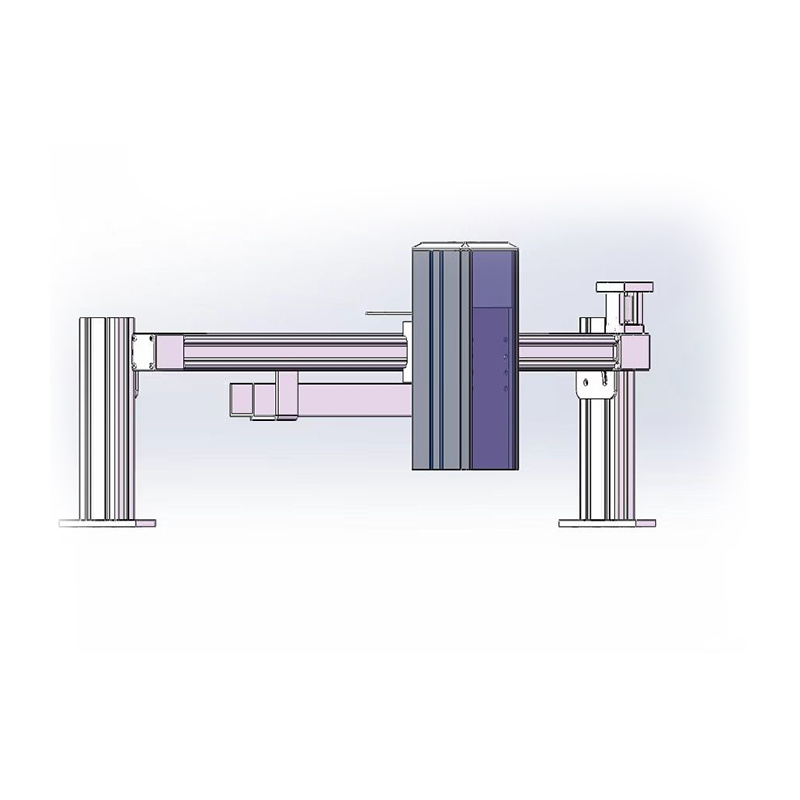

The Corona pretreatment system is a high-performance surface activation solution designed to enhance the adhesion of inks, coatings, and adhesives on non-conductive materials such as plastics, films, and foils. By generating a controlled corona discharge, the Corona pretreatment system modifies the molecular structure of the substrate surface, increasing its surface energy for optimal bonding. This process ensures stronger adhesion and more consistent print or coating results, even on low-energy materials like polyethylene and polypropylene. Widely used in packaging, labeling, extrusion, and printing industries, the Corona pretreatment system is an essential component for improving product quality and durability.

Engineered for efficiency and precision, the Corona pretreatment system integrates advanced power control technology, uniform electrode design, and intelligent feedback mechanisms to deliver consistent treatment across the entire web width. The system can be easily adjusted for various substrate types and thicknesses, providing stable performance at both low and high line speeds. Its modular structure allows seamless integration into new or existing production lines, while the real-time monitoring interface provides operators with accurate data on power output, voltage, and treatment intensity. This ensures that every surface receives the optimal level of activation for downstream processes such as printing, coating, or laminating.

Keywords:

Y Series - Corona Machine Controller

Previous Page

Next Page

Previous Page

Next Page

More Products

Online Message

If you have any suggestions, please leave a message or email us, and we will reply to you as soon as possible after receiving your message.