Standard-Definition Inspection System Continues to Play a Vital Role in Industrial Quality Control

Release Time:

14 Jan,2026

As manufacturing and industrial production continue to evolve toward higher efficiency and tighter quality requirements, inspection technologies remain a core component of modern production lines

As manufacturing and industrial production continue to evolve toward higher efficiency and tighter quality requirements, inspection technologies remain a core component of modern production lines. While high-resolution and AI-powered systems attract growing attention, the Standard-definition Inspection System continues to play a vital and practical role across a wide range of industries, offering stable performance, cost efficiency, and reliable results for many inspection tasks.

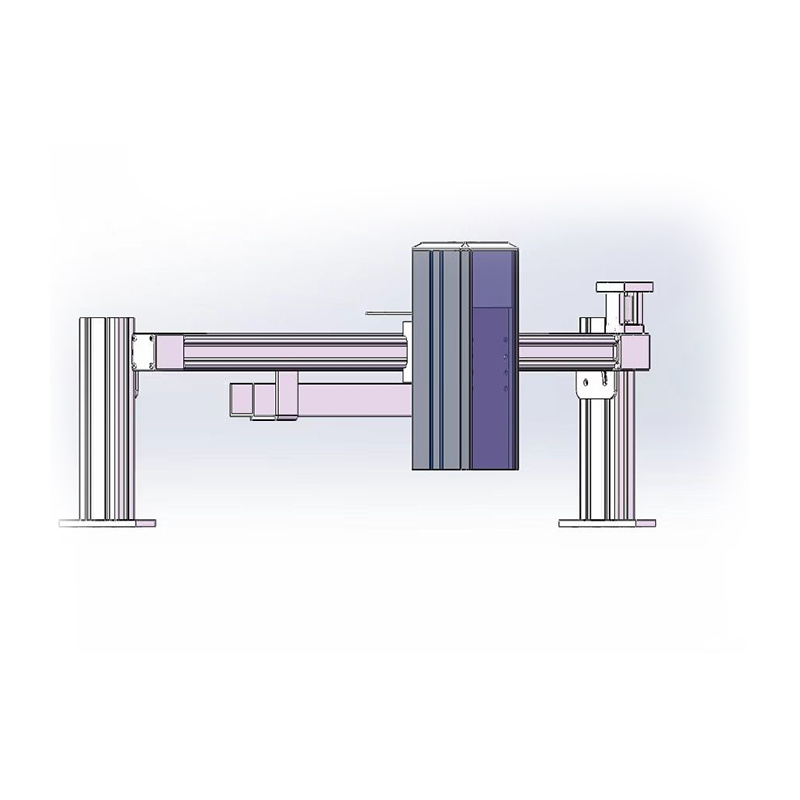

A Standard-definition Inspection System is designed to capture, process, and analyze visual information at standard resolution levels to detect defects, measure dimensions, and verify product consistency. For many production environments, especially those with clearly defined inspection criteria, standard-definition imaging provides sufficient accuracy without the added complexity or cost of ultra-high-resolution systems.

One of the key advantages of a Standard-definition Inspection System is its operational stability. These systems are well-established and widely tested in real-world industrial environments. Their mature hardware architecture and proven image-processing algorithms allow them to operate continuously with minimal downtime, making them suitable for long-term deployment on production lines that require consistent inspection performance.

Cost efficiency is another important factor driving the continued adoption of Standard-definition Inspection Systems. Compared with high-end inspection solutions, standard-definition systems require lower investment in cameras, lighting, processing units, and data storage. This makes them an attractive option for small and medium-sized manufacturers, as well as large-scale operations that need to deploy multiple inspection stations across different production stages.

In many applications, a Standard-definition Inspection System delivers more than enough performance to meet quality requirements. Typical use cases include surface defect detection, presence or absence checks, label verification, basic dimensional inspection, and process monitoring. When combined with optimized lighting and properly configured optics, standard-definition imaging can provide clear, reliable inspection results even in demanding industrial environments.

Another strength of the Standard-definition Inspection System lies in its ease of integration. These systems can be seamlessly connected with existing production equipment, programmable logic controllers, and manufacturing execution systems. This compatibility allows manufacturers to enhance quality control without major changes to their current production infrastructure, reducing implementation time and operational risk.

The flexibility of Standard-definition Inspection Systems also supports a wide range of industries, including electronics assembly, automotive components, packaging, food processing, pharmaceuticals, and general manufacturing. In these sectors, inspection tasks often focus on repeatable patterns and known defect types, where standard-definition imaging offers an effective balance between accuracy and efficiency.

From a maintenance perspective, Standard-definition Inspection Systems are generally easier to manage and support. Spare parts are widely available, system calibration is straightforward, and technical personnel are often already familiar with the technology. This reduces training requirements and helps ensure long-term system reliability.

As manufacturers continue to optimize production costs while maintaining quality standards, the role of the Standard-definition Inspection System remains highly relevant. Rather than being replaced entirely by advanced imaging solutions, standard-definition systems are increasingly positioned as practical tools for specific inspection tasks where ultra-high resolution is unnecessary.

Looking ahead, Standard-definition Inspection Systems are expected to evolve through improved software algorithms, better lighting control, and enhanced connectivity. These incremental advancements will further extend their service life and application range, ensuring that standard-definition inspection remains a dependable choice in modern industrial quality control strategies.

More Information